Reticle Haze Process Control using Weir PW

Sections (Links to 3 chapters)

1. Reticle-Haze sources, behavior and influence

2. Detection of reticle haze .

3. Process haze control .

Table of Contents

Introduction

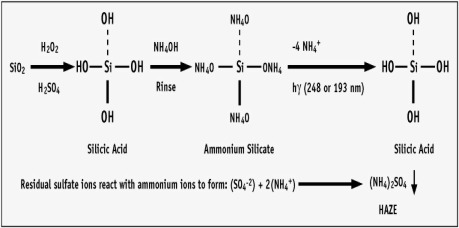

Reticle Haze is the formation of chemical residue as a result of film interactions that are initiated by Deep Ultra Violet (DUV) and higher frequency actinic radiation. Haze can for on the backside of the reticle, on the chrome side and on the pellicle itself.

The major component of the haze

constituent is known to be Ammonium Sulfate that is a residual of the cleaning

process and the interaction of the actinic radiation encountered during exposure

with the cleaning residue. Haze can form from sources found within mask-making

materials, process residues, the reticle storage container and the environment

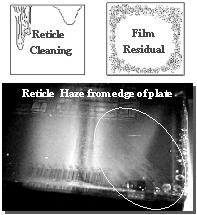

in which the reticle is used. An observation of the characteristic deposition signature of haze across the

reticle, as shown below, is a good indicator of the source of the contamination.

Note the large reticle area covered by the haze film.

An observation of the characteristic deposition signature of haze across the

reticle, as shown below, is a good indicator of the source of the contamination.

Note the large reticle area covered by the haze film.

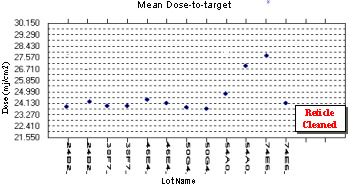

The most commonly observed effect of haze is a gradual loss in transmission of the reticle that results in a need to increase exposure-dose, as shown in the trend chart below. Since haze formation is non-uniform across the reticle, transmission loss results in an increase in the Across Chip Linewidth Variation (ACLV) and corresponding reduction in the manufacturing process window. Haze continues to grow as the reticle is exposed to additional low wavelength radiation.

The secondary effect of haze is to reduce wafer production capacity. Capacity is lost because reticle-scan speed must be reduced to increase the needed exposure of the reticle to achieve final image size. More importantly, capacity is strongly lowered because of a lowering of lithography yield in the form of more wafers entering the manufacturing rework loop.

The reticle is an active element

of the optical train of the exposure tool. Reticle haze therefore directly

contributes to the aberration signature of the lens influencing for feature size

and registration placement of the image.

Haze Initiation and Optical Influence

Haze deposition is a chemical reaction that first forms on the high-energy areas of the reticle known as "seed-sites'. Seed sites are not singularities that form at one or two isolated points on the reticle. Seed-sites also do not necessarily correspond to the areas around a chrome feature-edge although these will be high potential areas because of the scanner and change of refractive index that occurs at these points. Reticle repair sites, glass imperfections, localized index of refraction areas on the glass (known as "color centers") and chrome undercut regions can all act as host areas for the start of haze deposition and growth.

Haze initiation first forms across an extended area of the reticle surface covering millimeters or centimeters in extent. Formation speed is a function of localized feature density, the localized optical wavefront characteristics (lens edge verses center), the wavelength of illumination. Phase Shift Mask (PSM) technology reticles can initiate haze formation in areas of unequal etch or film thickness that results in non-optimum wave extinction during phase shifting.

Haze influence on the wavefront extends beyond that of a neutral-density filter change in intensity. Wavefronts are distorted both directly above the hazed areas and even for a significant extent adjacent to the areas. To understand these effects we will examine the behavior of a "grain" of haze located on three separate areas of the reticle.

Knife-edge

Optical Effects

To visualize the effects of haze formation at a chrome-feature edge, consider the opticians knife-edge. The thin chrome obscuration acts as a knife edge discontinuity. Knife edge analyses have been used for years in optics development because they allow the aberrations of the lens to be accurately measured.

The Profile at the edge of the knife edge is NOT a pure Dirac step function as assumed in a Gibbs Phenomenon modeling of side-lobe formation. It is a complex Intensity gradient that incorporates the a strong variance caused by optics- limited distortions, scatter and localized changes in the effective Numeric Aperture caused by the finite edge.

These perturbations result in an intensity profile that behaves like a Gibb’s function but is actually stronger in intensity and a more active variant across the focus and exposure-dose variances encountered in the process-space. The net effect of translucent obscurations interacting with feature edges is therefore greater than the Gibbs predicted, simple creation of intensity side-lobes in the image.

Chrome is not a true knife edge in that it’s thickness is actually many wavelengths in depth. The thickness therefore directly compounds profile changes by polarization and coherence perturbations. Chrome edge effects further amplify the aberrational influence

Scatter Effects

The chrome feature image is

further complicated in that it is supported by a quartz substrate. The wavefront

at the feature edge therefore encounters a change in the index of refraction

(Quartz-to-Air) at the same time that it encounters the chrome feature

obscuration.

The index change at the edge results in scatter and this in turn reduces the

edge resolution. The effect also interacts with the image wavefront to induce

localized aberrations.

AT&T, in 1982, was issued a series of patents for glass photomask coverplates to

protect the chrome photomask elements. The coverplate interface to the mask

incorporated an index matching fluid to prevent this scatter and reflection

interference. This patent also noted the improvement in image resolution and

depth-of-focus that resulted because the chrome was now encapsulated in a

continuous index of refraction and scatter was eliminated.

Open Area Haze

Formation

Haze does not form randomly. It needs a high-energy seed-site. Seed-sites start in areas containing:

Localized damaged from repair

Chrome Undercut

Impurities or localized stress in the quartz substrate

The resulting wavefront will be a convolution of the intensity profile across the hazed area PLUS the chrome edge. Profiles from nearby features as far as two microns away PLUS the scatter added by the chrome edge, haze edge and internal haze phase boundaries from acrylic crystalline transitions. The translucent haze-area behaves as a micro-lens and will introduce refractive aberrations that further interfere with the wavefront.

Summary: Isolated haze introduces wavefront distortions and aberrations that influence nearby features.

Chrome-obscured

haze

Chrome is not a complete

obscuration of the wavefront. It’s complex index of refraction results in a

portion of the electromagnetic wave that penetrates the thin film and interacts

with the overall image formation. In short, chrome is translucent even at

deep-UV illumination.

The wavefront amplitude and phase immediately above the chrome surface is not

zero. A haze element will react with the chrome causing thinning, cracking and

other localized physical reactions.

Scatter from other parts of the imaging layer will interact with this wavefront

and also be gathered by the lenticular behavior of the translucent haze. This

results in localized aberrations of near feature-edge images not directly involved with

the haze seed.

Summary: On chrome haze has a smaller but still finite perturbing influence on

the wavefront that introduces aberrations and scatter.

Summary

Haze formation is a process

phenomenon that initiates on high-energy areas of the reticle and encompass

large areas.

The most widely recognized response associated with reticle-haze is a requirement to increase exposure-dose in order to restore proper feature size.

Early haze formation does not have to be intimately associated with a feature edge to influence overall image quality. Early seed-formation results in isolated haze segments that act as "micro-lens" elements placed directly on the object surface of the lens system. Even haze formation located directly on a chrome surface can influence the overall flare and dark-image formation of the optical train.

During image formation, the photomask-object is converted to a frequency spectrum at the entrance pupil of the lens. Scatter and aberrations from haze perturb this spectrum and also change the influence of the inherent lens aberrations on the image. The overall effect results in large-area image degradation. Since all lenses retain finite coma and spherical aberration as balanced aberrations tuned to the ideal photomask image, the tuning of the lens rapidly degrades over the entire image area.

This interaction results in an aberrational influence on the wavefront that negatively influences the shape and size of the manufacturing process window. As shown in the picture above, this results in asymmetric response and degradation of Best Focus, Depth of Focus and the Exposure latitude of the production sequence. Normal process-space variation will therefore result in a direct loss of lithographic yields, an increase in rework rates and an ultimate loss in overall final-test yield.

Next Section to read: Detection of reticle haze

* DoseMapper is a trademark of ASM Lithography, http://www.asml.com

** CDC101 is a product of Pixer Technology, http://www.pixertech.com

*** TeraStar is a product of KLA-Tencor, http://www.KLA-tencor.com

* Excel is a trademark of Microsoft Corporation

* ASML is a tradename of ASM Lithography

ã Copyright 2007 TEA Systems Corporation, All rights reserved. Legal

TEA Systems

Corp. | Tel: +1 610 682 4146

65 Schlossburg St., Alburtis, PA USA